DALY Manufacturing

Daly has internationally advanced production lines and comprehensive high-precision production equipment. It also introduces a variety of production and testing equipment to meet the production needs of different varieties and specifications. We implement a combination of automated production and data management systems to achieve high efficiency and flexibility while ensuring that the quality of all BMS products produced by Daly is at a stable and high-quality level.

DALY Production Strength

20,000㎡ production base

Highly automated production line

Lean production and efficiency improvement

1,000,000+monthly production capacity

MES intelligent production management

Internationally leading production technology

Manufacturing Vision

High Standard

Daly strictly implements ISO9001 production management standard operating procedures and implements an efficient operating model. The production process and quality management are much higher than international standards. In recent years, Daly has continuously refreshed industry standards. Customers from more than 100 countries and regions around the world recognize it as the best embodiment of excellent quality.

Fine Manegement

Daly implements "Fine Management" of every production, and all aspects of the product from raw materials to finished products have been meticulously monitored and inspected by Daly.

Zero-defect

Daly comprehensively implements "workflow analysis", "management design of specific work steps", "extraction of design and manufacturing problems and implementation of measures", and "implementation of work points" to all employees at the production sites, with the goal of ensuring "zero defects" in every Daly BMS by enabling all employees to grasp the purpose, operation methods, and implementation of their own processes in a safe and quality-assured production process.

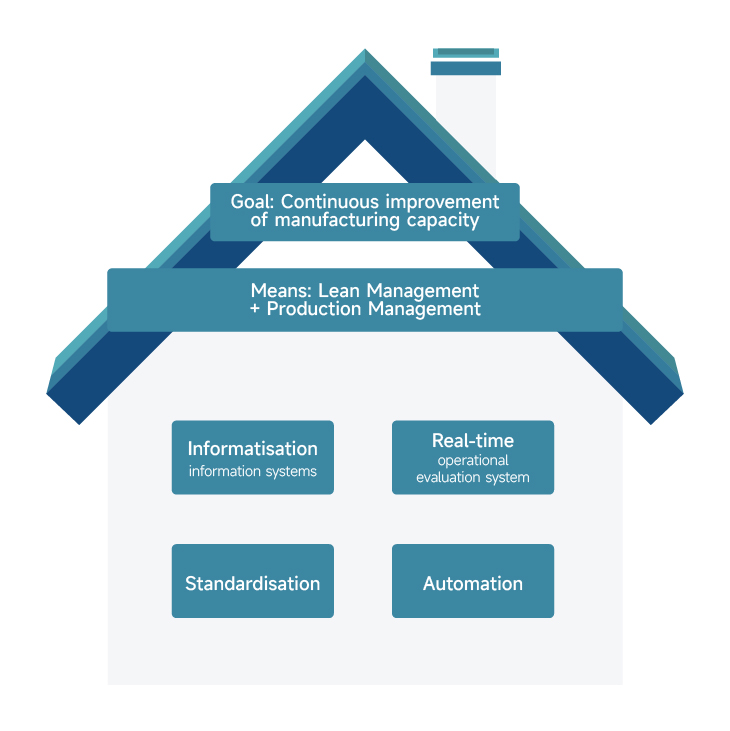

Manufacturing System