Lithium batteries have become an indispensable part of the new energy ecosystem, powering everything from electric vehicles and energy storage facilities to portable electronics. Yet, a common challenge faced by users worldwide is the significant impact of temperature on battery performance—summer often brings issues like battery swelling and leakage, while winter leads to drastically reduced range and poor charging efficiency. This is rooted in the inherent temperature sensitivity of lithium batteries, with lithium iron phosphate batteries, one of the most widely used types, performing optimally between 0°C and 40°C. Within this range, the internal chemical reactions and ion migration operate at peak efficiency, ensuring maximum energy output.

Temperatures outside this safe window pose severe risks to lithium batteries. In high-temperature environments, electrolyte volatilization and decomposition accelerate, lowering ion conductivity and potentially generating gas that causes battery swelling or rupture. Additionally, the structural stability of electrode materials deteriorates, leading to irreversible capacity loss. More critically, excessive heat can trigger thermal runaway, a chain reaction that may result in safety incidents, which is a major cause of malfunctions in new energy devices. Low temperatures are equally problematic: increased electrolyte viscosity slows lithium ion migration, raising internal resistance and reducing charge-discharge efficiency. Forced charging in cold conditions can cause lithium ions to precipitate on the negative electrode surface, forming lithium dendrites that pierce the separator and trigger internal short circuits, posing significant safety hazards.

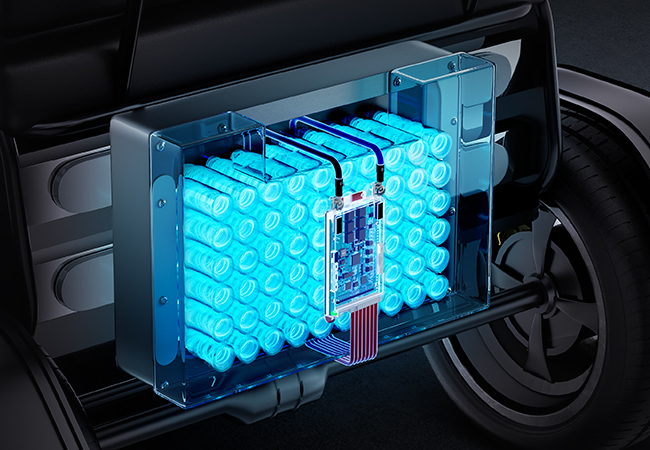

To mitigate these temperature-induced risks, the Lithium Battery Protection Board, commonly known as BMS (Battery Management System), is essential. High-quality BMS products are equipped with high-precision NTC temperature sensors that continuously monitor battery temperature. When temperatures exceed safe limits, the system triggers an alarm; in cases of rapid temperature spikes, it immediately activates protective measures to cut off the circuit, preventing further damage. Advanced BMS with low-temperature heating control logic can also create optimal operating conditions for batteries in cold environments, effectively addressing issues like reduced range and charging difficulties, ensuring stable performance across diverse temperature scenarios.

As a core component of the lithium battery safety system, a high-performance BMS not only safeguards operational safety but also extends battery lifespan, providing critical support for the reliable operation of new energy equipment.

Post time: Oct-23-2025